Keeping your cable manufacturing machines in tip-top shape isn’t just a good idea—it’s essential. These machines are the heartbeat of your production line. If one breaks down, everything halts. And in a world where every second counts, downtime equals lost money. But here’s the good news: with the right strategies, you can minimize downtime and maximize productivity. So, let’s dive into what it really takes to keep your cable machinery running like a dream.

Understanding the Importance of Machine Maintenance

Why Machine Uptime Is Crucial in Cable Manufacturing

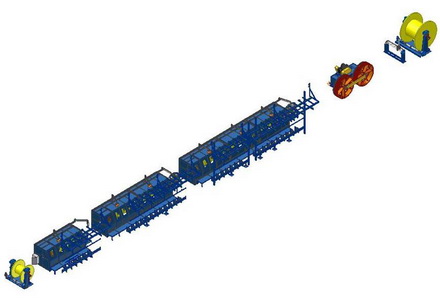

Cable manufacturing is all about precision and consistency. These cable manufacturing machines are built to handle repetitive, high-speed tasks without error. But the catch? They need to be running constantly to hit production targets. When your machines are up and running, your business is making money. But as soon as they stop, everything backs up—from order fulfillment to customer satisfaction.

Imagine this: You’ve got a big contract to deliver thousands of feet of specialty cable. Your machines break down halfway through. Now you’re dealing with delays, scrambling for repairs, and possibly losing the client. That’s how critical uptime is.

The better maintained your machines are, the smoother everything else flows. Uptime isn’t just about quantity; it also improves quality. Poorly maintained machines make more mistakes, leading to defective products. And let’s be real—no one wants a batch of faulty cables heading out the door.

The Costs of Downtime and Poor Maintenance

Every minute of unplanned downtime eats into your bottom line. You’re not just losing production—you’re also paying idle workers, delaying shipments, and risking penalties for missed deadlines. But it gets worse. Neglecting maintenance often leads to more serious breakdowns, which means more expensive repairs and even longer recovery times.

Then there’s the hidden cost: your reputation. If customers start seeing you as unreliable, they’ll look elsewhere. Maintenance may seem like a cost on paper, but in reality, it’s an investment in reliability and trust.

Want to stay competitive in a cutthroat market? Prioritize machine uptime like your business depends on it—because it absolutely does.

Creating a Proactive Maintenance Schedule

Preventive vs. Reactive Maintenance

Let’s clear something up: waiting for your machine to fail before fixing it is a recipe for disaster. That’s reactive maintenance—and it’s risky. Preventive maintenance, on the other hand, is all about staying ahead. It’s like changing the oil in your car before the engine seizes. Sure, it takes time and effort upfront, but it saves a ton of headaches later.

Preventive maintenance includes tasks like checking belts, replacing worn parts, cleaning sensors, and lubricating joints. These might seem small, but they make a huge difference in long-term performance. The goal? To fix problems before they start.

Reactive maintenance has its place—sometimes things do break without warning. But if you’re always putting out fires, you’re never moving forward. Preventive maintenance keeps you in control.

Daily, Weekly, and Monthly Maintenance Tasks

Here’s how you break it down:

- Daily Tasks: Check machine alignment, look for unusual noises, clean surface debris, inspect cables for frays.

- Weekly Tasks: Inspect lubrication levels, check sensor accuracy, clean air filters, test machine responsiveness.

- Monthly Tasks: Deep clean machines, recalibrate systems, inspect internal components, analyze performance data.

Each task plays a part in extending your machine’s life. Create a checklist, assign responsibilities, and stick to the schedule like clockwork.

Examples of Maintenance Checklists

A good checklist might look like this:

Daily:

- Inspect belts for tension

- Check coolant levels

- Listen for irregular sounds

Weekly:

- Verify sensor readings

- Clean external and internal filters

- Check for software updates

Monthly:

- Conduct vibration analysis

- Tighten loose bolts and connectors

- Test safety shutoff systems

These aren’t just busywork—they’re the backbone of a reliable operation. Want fewer breakdowns and more peace of mind? Stick to your maintenance schedule religiously.

Training Your Workforce Effectively

Role of Skilled Technicians in Smooth Operation

Your machines are only as good as the people running them. Even the most advanced cable manufacturing system can grind to a halt in the hands of an undertrained operator. Skilled technicians are your first line of defense against inefficiency and breakdowns. They know what to listen for, what to look out for, and how to catch minor issues before they snowball.

Think of your technicians as machine whisperers—they should be able to sense when something’s off before alarms start blaring. That level of awareness only comes with proper training and hands-on experience.

You wouldn’t hand the keys to a race car to someone who’s never driven stick, right? Then don’t let untrained staff near your high-value equipment.

Providing Ongoing Technical Training

Technology evolves. So should your training programs. Don’t assume a one-time workshop is enough. Create a culture of continuous learning where team members stay updated on the latest systems, tools, and safety protocols.

Offer refresher courses, online certifications, and manufacturer-led training sessions. Make sure your employees are familiar with the latest software updates, new diagnostic tools, and industry best practices.

Also, encourage cross-training. When more team members understand how the machines work, you reduce your reliance on a handful of key personnel. That kind of flexibility can be a game-changer during staff absences or peak production periods.

Investing in people is just as important as investing in machines. When your team grows, your productivity grows with it.

Regular Lubrication and Cleaning Routines

Importance of Keeping Components Clean

Dust, debris, and grime are silent killers in cable manufacturing. Over time, they clog up sensors, wear down moving parts, and cause overheating. Clean machines not only run better but also last longer.

Dirty environments invite mechanical issues—motors get jammed, bearings seize, and belts snap. And once something breaks, the whole production line could be in jeopardy. So why not prevent all that with simple, routine cleaning?

A clean machine is also easier to inspect. Technicians can spot leaks, cracks, and misalignments faster without having to wipe off layers of gunk first. It’s a win-win.

Want to keep your machines happy? Grab that vacuum and air compressor more often.

Choosing the Right Lubricants for Different Parts

Not all lubricants are created equal. Using the wrong oil or grease can actually harm your equipment. Every moving part—bearings, gears, rollers—has specific needs. Too much lubricant can cause build-up and overheating, while too little creates friction and wear.

Stick to manufacturer recommendations for each component. Store lubricants in a clean, dry area, and label them clearly to avoid mix-ups. Also, check expiration dates—yes, lubricants can go bad!

Use automated lubrication systems if possible. They deliver the perfect amount at the right intervals, taking the guesswork out of the process. It’s a small upgrade that can prevent big problems.

Upgrading and Retrofitting Aging Equipment

When to Consider Upgrading Your Machinery

Every machine has a lifespan. Sure, you can keep an old one running with band-aid fixes, but at some point, the cost of maintenance outweighs the benefits. How do you know when it’s time to upgrade?

Here are some signs:

- Increasing frequency of breakdowns

- Inability to meet modern production demands

- High energy consumption

- Lack of compatibility with new software or automation tools

Upgrading your machinery isn’t just about avoiding breakdowns—it’s about improving speed, quality, and flexibility. Newer machines offer better control systems, energy efficiency, and integration with digital platforms.

If your competitors are running high-tech lines while you’re still using equipment from the 90s, you’re falling behind. Upgrades aren’t just maintenance—they’re business strategy.

Cost-Benefit Analysis of Retrofitting vs Replacing

Sometimes, full replacement isn’t feasible. That’s where retrofitting comes in. Retrofitting allows you to modernize old machines with new components—like control systems, sensors, or automation modules—without the cost of buying new equipment.

Let’s compare:

Retrofitting Pros:

- Lower cost than new machinery

- Faster implementation

- Extends useful life of current equipment

- Customizable to specific needs

Replacement Pros:

- Higher efficiency and speed

- Lower energy consumption

- Fewer compatibility issues

- Full warranty and support

The key is knowing what your operation truly needs. If the machine frame is solid and just the electronics are outdated, retrofitting is a smart move. But if you’re dealing with structural wear or constant failures, replacement might be the wiser investment.

Talk to equipment specialists and run the numbers before making a decision. Either way, staying stuck in the past is not an option.

Conclusion

Keeping your cable manufacturing machines running smoothly isn’t just about maintenance—it’s about mindset. It’s about building a system that values uptime, trains its people, monitors performance, and plans for the unexpected. From daily cleaning routines and lubricant choices to advanced IoT systems and emergency protocols, every detail matters.

By following the strategies we’ve laid out—from creating proactive schedules to fostering a culture of continuous improvement—you’re not just avoiding breakdowns. You’re building a resilient, efficient, and future-ready operation. Machines are only as good as the systems and people supporting them. So invest wisely, plan thoroughly, and always look for ways to improve.

Because in cable manufacturing, smooth operations aren’t just nice to have—they’re the difference between leading the industry and lagging behind.